Quality Control

At Reasa®, we pay special attention to selecting raw materials using certified carbon-grade steel.

We analyze the variables in our manufacturing processes to ensure our products' quality and customer satisfaction.

REASA has an advanced laboratory for chemical and mechanical tests to comply with the requirements of our customers according to the International Standards ASTM-A407 and JIS G-3521.

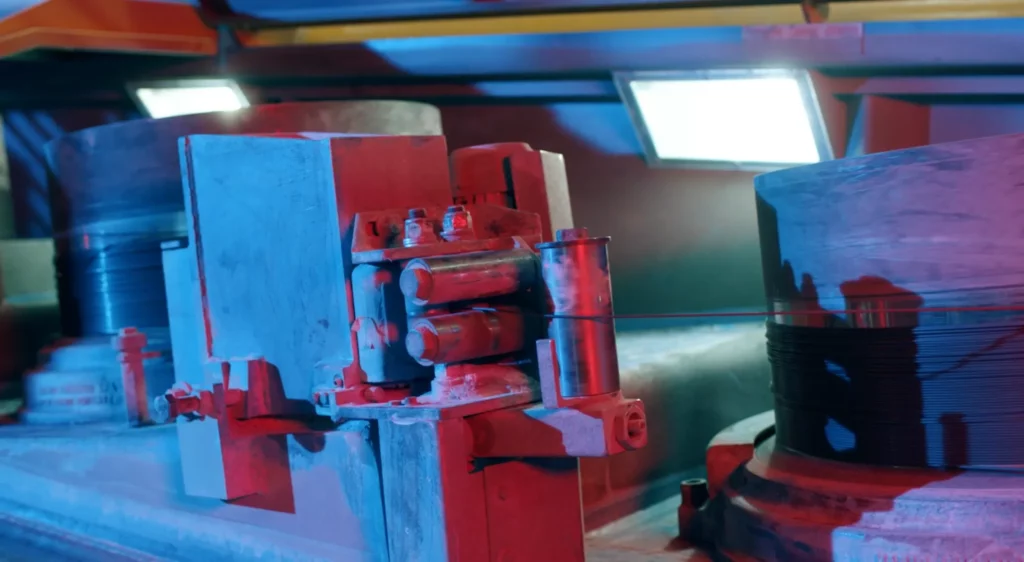

WIRE DRAWING PROCESS

It consists of drawing wire rods in the cold and reducing the section of the wire when it is passed through a die with a conical hole. This reduction provides the material with an increase in hardness to the benefit of its mechanical characteristics.

CHEMICAL ANALYSIS OF STEEL

Our company stays ahead of technology to meet the demands of our quality controls and customers. We recently acquired a state-of-the-art laser spectrometer from Germany to perform thorough chemical analyses of our steel products.

Diameter and ovality measurement with laser technology.

Diameter and ovality measurement with laser technology, according to ASTM A407 standards.

The tensiometer guarantees wire quality according to ASTM A407 and JIS3521 standards.

Torque meter, torque measurement by means of turns.

Lubricant residual film measuring instruments.

Laser spectrometer to determine the chemical composition of the steel.